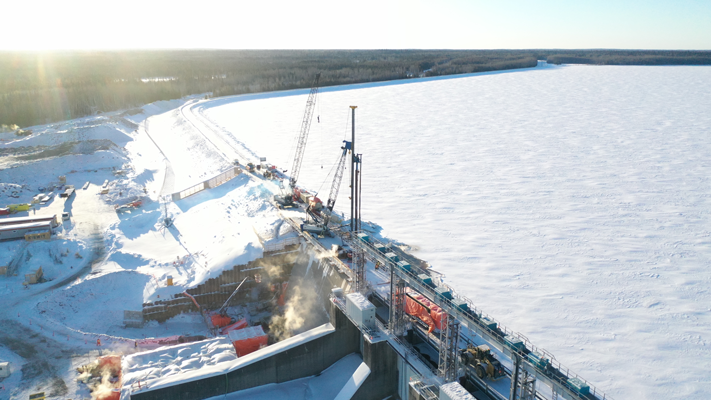

Little Long Dam

The Little Long Hydroelectric site, built in the 1960s, is the first of a series of four sites developed along the Mattagami River.

The Little Long Dam Safety Project is underway to increase the discharge capacity at this spillway structure to comply with updated requirements established by the Province of Ontario. The company is in the process of adding four new sluiceway passages, which control water levels and flow rates in rivers, at the Adam Creek Sluiceway Structure. The owner Ontario Power Generation (OPG) is also making reliability improvements to the existing Little Long (2) and Adam Creek (8) sluice gates.

- Employer/Owner: Ontario Power Generation

- Client: Kiewit

- Execution: Bauer Foundations Canada Inc. (BFCA)

Location

The Little Long Dam Safety Project site is located in Northeastern Ontario, 70 km North of Kapuskasing, Ontario on the Little Long headpond

Scope of work

Bauer was awarded the contract to construct two temporary cofferdams. The cofferdams would allow for the construction of four additional sluiceways, thereby increasing the overall discharge capacity at the Adam Creek spillway structure. The main scope of work included the following:

- Mobilization of drilling and support equipment for each construction activity.

- Supply and install template/falsework.

- Drill and install interlocked O-Piles (24” O-Pile).

- 128 Total Piles – 24” O-Piles.

- 64 Piles per cofferdam (depth: 21 m from working platform).

- Cement/Bentonite grout to seal O-Piles rock socket.

- Top waler installation.

- Seal O-Pile at both ends connecting to the existing to the gravity dam.

- Excavate inside the cofferdam down using clam bucket.

- Install bottom waler.

- Supply and install tie back anchors into the gravity dam.

- Removal/extraction of waler systems and O-Piles once construction of the new sluicegates are complete.

On each side of the Adam Creek Sluiceway Structure, approximately 25 to 30 piles – out of 64 – were drilled through the top layer of the dike core and overburden soil that consisted of clay, sand and boulders above bedrock.

Away from this area, the piles were starting well in bedrock with a layer of boulders on top ranging from 200 mm to 800 mm in size. As per design, rock socket of 3.5 m to 4.5 m was achieved on the project with 3.5 m being in the area of existing overburden and dike core, (i.e.: closer to the dam face and away from the existing sluicegates).

Geology

The bedrock was identified as metasediment bedrock (Biotite Gneiss) with some quartz veins, typically consisting of slightly weathered to fresh weathering, in a non-porous and medium to strong condition. On the basis of the recorded RQD values, the rock quality is estimated to be generally “Fair” to “Excellent”. The average RQD value of approximately 92 % was observed suggesting a rock of generally “Excellent” quality. The UCS of the tested samples (intact rock of suitable core length) ranged from 55.8 to 169.5 MPa.

Equipment

- 2 x Terex HC110 Crawler Crane

- Berminghammer L23 Vertical Tracking Lead

- Mincon MP180 DTH Hammer

- Pinnacle Reverse Circulation Rotary Head

- Mincon Integrated O-Pile Ring Bit System

- American Pile Driving Equipment (APE) 200-6 Vibro with 700 Power Unit

- 3 x 1170 CFM Air Compressors

Construction period

Phase 1 – East Cofferdam

- Pile Installation: November 2020 – April 2021

- Break for spring freshet and other activities on-site

- Bracing: August 2021 – November 2021

Phase 2 -West Cofferdam

- Pile installation: November 2021 – January 2022

- Bracing: January 2022 – June 2022 (break during spring freshet 1.5 months)

Miscellaneous

Pile installation of the project was executed in extreme winter conditions with temperatures well below -30 degrees Celsius.

- Project phase was completed on schedule.

- Day and Night shift operation (24/7) with camp stay.